In the realm of surface protection and enhancement, nano coatings have emerged as a revolutionary solution. These coatings, known for their ultra-thin layers and exceptional durability, offer a range of benefits from repelling water and dirt to enhancing the aesthetic appeal of surfaces.

However, a common query among users pertains to the drying time of clear coats in nano coatings. Understanding this aspect is crucial for ensuring optimal application and results.

What is Nano Coating?

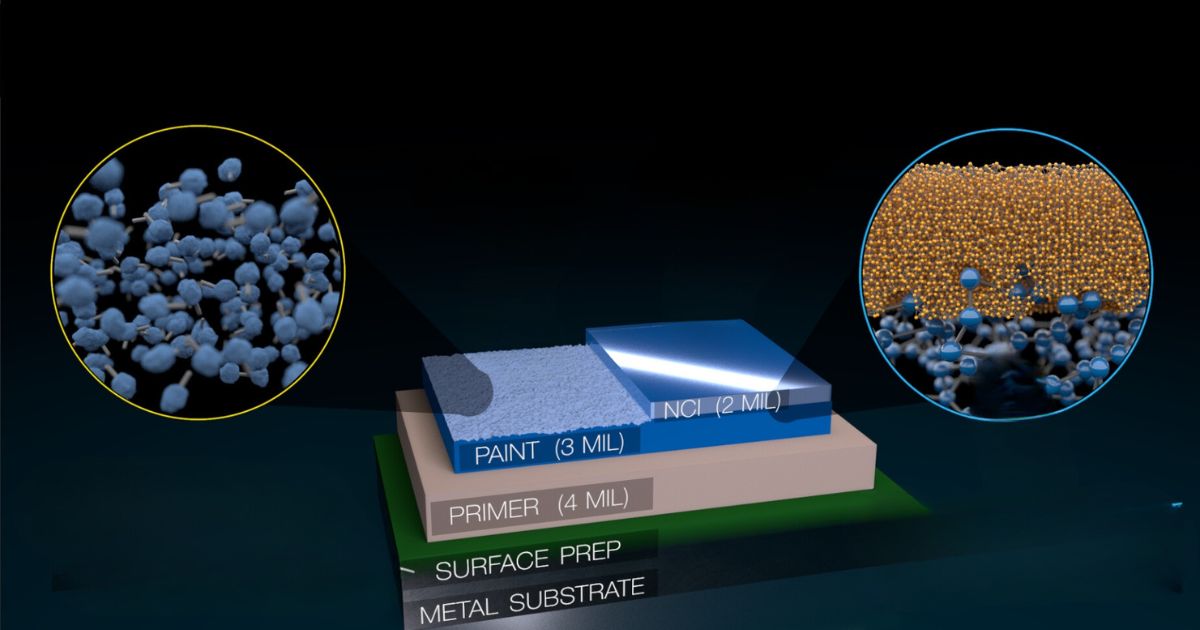

Nano coatings, also referred to as nano sealants or nano ceramic coatings, are advanced formulations primarily composed of nanoparticles. These nanoparticles create an ultra-thin protective layer when applied to surfaces such as automotive paint, glass, metal, and plastic. This layer provides numerous benefits including enhanced scratch resistance, UV protection, hydrophobicity, and resistance to chemical damage.

Clear Coat in Nano Coatings

Clear coat, a vital component of nano coatings, serves as the protective barrier that seals the surface and provides the desired properties. It is responsible for imparting the glossy finish associated with nano coatings while ensuring longevity and resilience against environmental factors.

Drying Time of Clear Coat

The drying time of clear coat in nano coatings can vary depending on several factors:

- Formulation: Different nano coating products may contain variations in their formulation, leading to differences in drying times. Manufacturers often provide guidelines regarding drying times based on their specific product formulations.

- Ambient Conditions: Environmental factors such as temperature, humidity, and airflow play a significant role in the drying process. Warmer temperatures and low humidity levels generally facilitate faster drying, while cold and humid conditions can prolong the drying time.

- Application Method: The method of application, whether it’s spraying, wiping, or brushing, can influence the drying time. Uniform application and adequate curing time are essential for achieving optimal results.

- Thickness of Application: The thickness of the clear coat layer applied can impact the drying time. Thicker layers may require more time to dry completely, while thinner layers may dry relatively faster.

Typically, nano coating manufacturers recommend allowing the clear coat to dry for a specific period before exposing the treated surface to water or other environmental factors. This curing period allows the coating to adhere properly and develop its full protective properties.

Factors Affecting Drying Time

- Temperature: Ideal drying conditions range between 20°C to 30°C (68°F to 86°F). Higher temperatures accelerate the drying process, while lower temperatures slow it down.

- Humidity: Low humidity levels facilitate faster drying, while high humidity can prolong it. Ideally, humidity levels should be below 50% for optimal drying.

- Ventilation: Adequate airflow helps in speeding up the drying process by facilitating the evaporation of solvents in the coating.

Conclusion

In conclusion, the drying time of clear coat in nano coatings is influenced by various factors including formulation, ambient conditions, application method, and thickness of application. Understanding these factors and following manufacturer guidelines is essential for achieving the desired results.

While drying times may vary, allowing sufficient curing time is crucial for the nano coating to develop its full protective properties and ensure long-lasting performance.